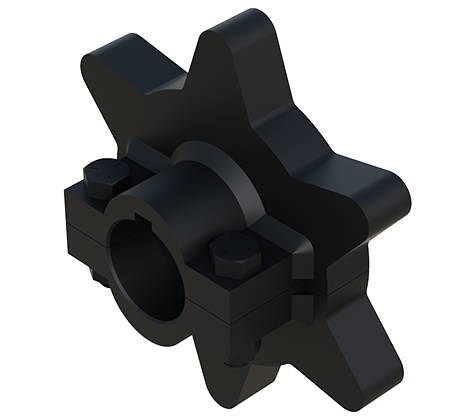

Black Ace Sprockets play an integral role when conveying product. Whether it’s on an assembly line that runs 24/7 or an agricultural harvester used annually, production halts when sprockets don’t perform.

|

SPROCKET SERIES

|

67T |

|---|---|

|

CHAIN PITCH (INCHES)

|

2.56 |

|

Chain Roller Diameter

|

1.187" |

|

Plate Thickness

|

3/4" |

|

Common Designations

|

T67 – 67 T-BAR |

|

NUMBER OF TEETH

|

PITCH DIAMETER |

| 6 | 5.12 |

| 7 | 5.90 |

| 8 | 6.69 |

| 9 | 7.48 |

| 10 | 8.28 |

| 11 | 9.09 |

| 12 | 9.89 |

| 13 | 10.70 |

| 14 | 11.50 |

| 15 | 12.31 |

| 16 | 13.12 |

| 17 | 13.93 |

| 18 | 14.74 |

| 19 | 15.55 |

| 20 | 16.36 |